9 Holes per Second Video

We achieve the incredible rate of 9 holes per second due to the Eagle iNspire Series 6g acceleration. The Eagle is faster than some cluster punches, but without any tooling. And, Eagle is low operating cost and reliable for 24/7 operation due to the patented eVa© cutting head. Let us show you what this machine can do on your parts.

7 holes per second – 11 gauge

0.2″ thick steel with 3/16″ holes. This video may be more impressive than the 9 holes per second video above. Only the Eagle iNspire® Series of fiber laser machine tools with 15kW of power can pop 3/16″ holes at 7 holes per second (imagine what you can do with Eagle’s 20kW). The holes easily met tolerance and the speed exceeded our customer’s expectations.

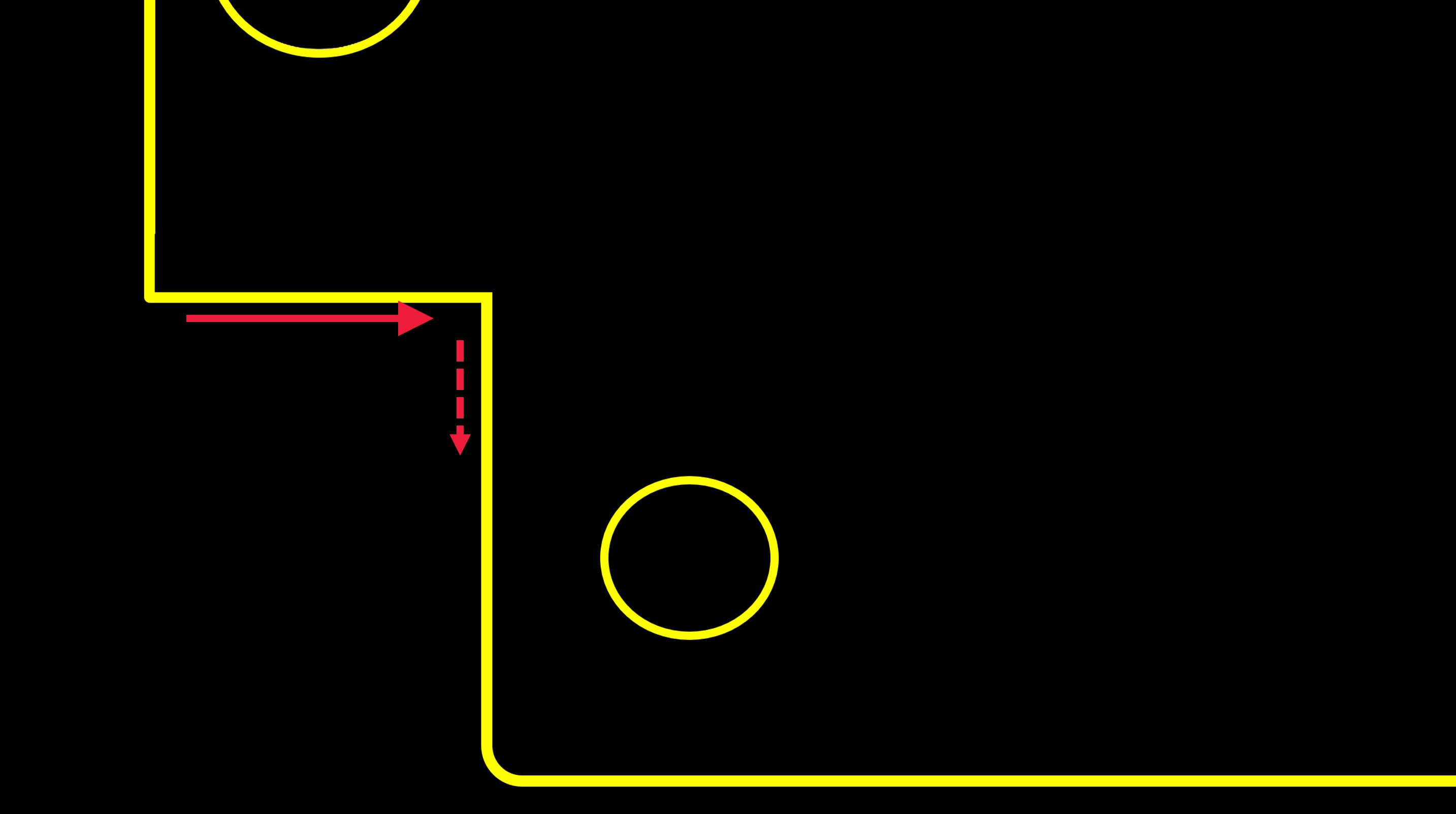

Negotiate Corners Faster with 6g Acceleration

Double the Gs and you cut in half the time and distance it takes to get up to speed. If the fiber laser is cutting left to right as shown by the solid red arrow, the machine will have to accelerate at the beginning of the segment and then decelerate as it approaches the corner. If the machine is not quick enough, then it’s likely the laser will never reach the programmed cut speed on this short segment before it has to start decelerating at as it prepares for the right hand turn (in direction of the dotted line).

Designed for Acceleration

- Linear motors are used on all 3 axes (yes, even the Z)

- Polymer granite base, such as used on CMMs, provides ultimate rigidity, temperature stability, and vibration dampening

- Gantry configuration is idealized for low weight and high stiffness

- On the Eagle iNspire the bridge is carbon fiber – 2.5 times lighter than steel yet delivering greater stiffness and vibration dampening

- Eagle iNspire = 6g acceleration, eVision = 3g acceleration, and eSmart = 2g acceleration