Eagle Fiber Lasers

Nothing Faster.Eagle is the fastest growing fiber laser systems manufacturer in Europe and they formally came to North America in 2018 through Fairmont Machinery. Eagle pioneered fiber laser for sheet and plate metal cutting with their long-standing partner IPG Photonics. Eagle manufactures the world’s most advanced and reliable fiber lasers. Link: Eagle Laser Website

Fairmont Machinery is the US master importer and distributor for Eagle Lasers. We cover sales and service, and hold a vast inventory of spare parts. With our nationwide network of partners we have a representative near you.

But what makes it the world’s most productive?

Three reasons:

1

Highest Power

Eagle offers 2 to 30kW fiber lasers. Eagle power deliver cut speed 2 to 4 times faster than other lasers, while the exclusive and patented eVa high-power cutting head ensures full reliability and uptime. Even at 30kW, Eagle is ready for 24/7 operation in your shop.

2

Highest Acceleration

Cut speed is useless if your laser can’t accelerate to top cut speed fast enough. Where other machines deliver 1 to 3 G acceleration, Eagle delivers up to 6 G’s. Motion speed of 13,780 inches/minute coupled with 6 G acceleration makes this machine faster than your eye can track.

3

Fastest Material Handling

Eagle’s 9-second pallet changer is designed not only to be the fastest, but also the most reliable. Servo drives replace slow hydraulics, and mechanical engagement ensures flawless and reliable operation day in and day out.

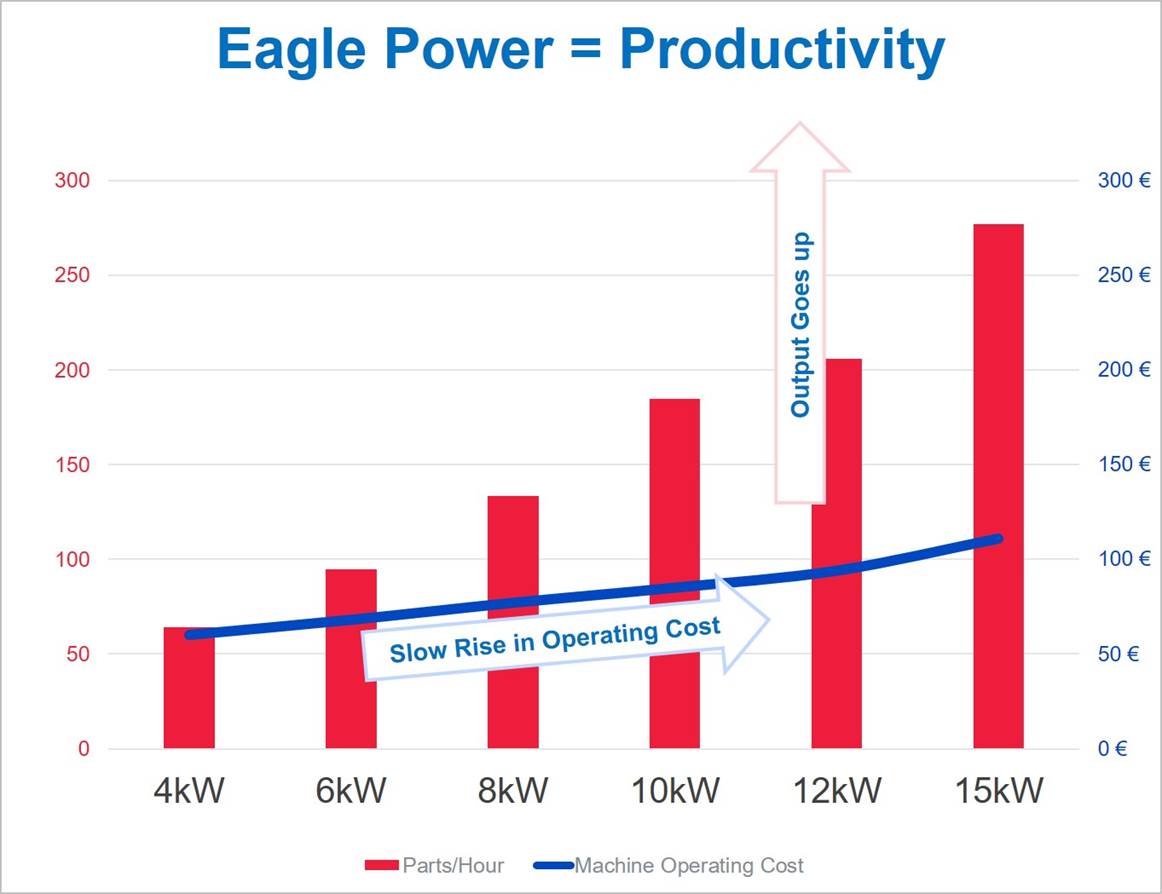

Highest Power

Increasing power not only produces more parts per hour, but significantly drops the cost per part. Now available with 30kW.

More Power = More Profit

Highest Acceleration

6G accelerates and decelerates in 1/6 the distance and time as a typical 1G machine. Cornering and rapid traverse moves are faster.

Produce parts faster with the quickest laser available.

Fastest Pallet Change

Most fiber laser machines boast of a 25 to 60 second pallet change. Eagle’s integrated pallet changer takes only 9 seconds on our 5×10′ machine. A machine this fast needs to be fed. Eagle manufactures a full line of material handling automation and towers.

6 Steps to an Ideal Fiber Laser Machine

Design mechanical structure for high-speed motion

On the Eagle iNspire series of machines, performance starts with the structural design and materials. Two polymer concrete bases weighing nearly 10,000 pounds each provide temperature stability, rigidity, and vibration dampening. The bridge is made of a unique carbon-fiber composite that is far stiffer and 2.5x lighter and far greater temperature stability than steel. The bridge is placed directly between the bases to minimize length and weight, ideal for high G dynamic motion.

Design a ridiculously fast drive system

Eagle utilizes ultra-powerful linear drives and Renishaw absolute linear encoders on all axes coupled with Beckhoff high-speed digital control to achieve a maximum traverse velocity of 13,780 inches per minute (350 m/min). Eagle is the fastest laser available.

Design for extreme acceleration, or your machine will never reach top speed

The hidden curse of ultrahigh-speed motion is vibration. Eagle’s polymer concrete base is heavy, the bridge is light and short, the bridge is driven from the center of gravity, the linear motor drive is non-contact, and the electrical system has sophisticated vibration dampening algorithms. The result is 6g of acceleration/deceleration, up to 5x that of other high-speed fiber lasers. Eagle had to redesign the front doors of the Eagle because the bridge motion actually pushed enough air to throw the doors open.

Select high power laser to take advantage of the motion characteristics

Fiber lasers can be ganged to nearly unlimited power levels (a fiber laser has been delivered 150 kW for special R&D applications). Once you exceed 6 kW of fiber laser power the weakest link in the reliability chain for the system is the head. Since the beginning, Eagle worked tirelessly with IPG Photonics to understand the issues. The result is Eagle’s exclusive and patented eVa cutting head and optics system – the only reliable high-power fiber laser head available today capable of 24/7 operation, even at 30kW.

Design material handling pallet changer to be fast

When you cut sheets this quickly, you’re changing pallets 6 to 10 times per hour. Material handling becomes a large part of the total part cost. Since time changing sheets is wasted time, Eagle has developed a servo driven (not hydraulic driven) pallet changer that exchanges pallets in just 9 seconds on our 5×10′ machine, as compared to 25 to 65 seconds. Both pallets move at the same time.

Select only the best sub component partners to provide the greatest reliability

Eagle partners with the best-in-class suppliers of every component and sub-system. Beckhoff – renowned supplier of ultra-fast, most reliable advanced motion controls , IPG – the inventor and world leader of fiber laser, Renishaw – leader in measurement and feedback systems, Festo – leader of pneumatic technology, and Nord, leader in reliable gear boxes just to name a few. These quality components deliver great reliability, and their North American facilities offer local support.

Full Line of Eagle Machines

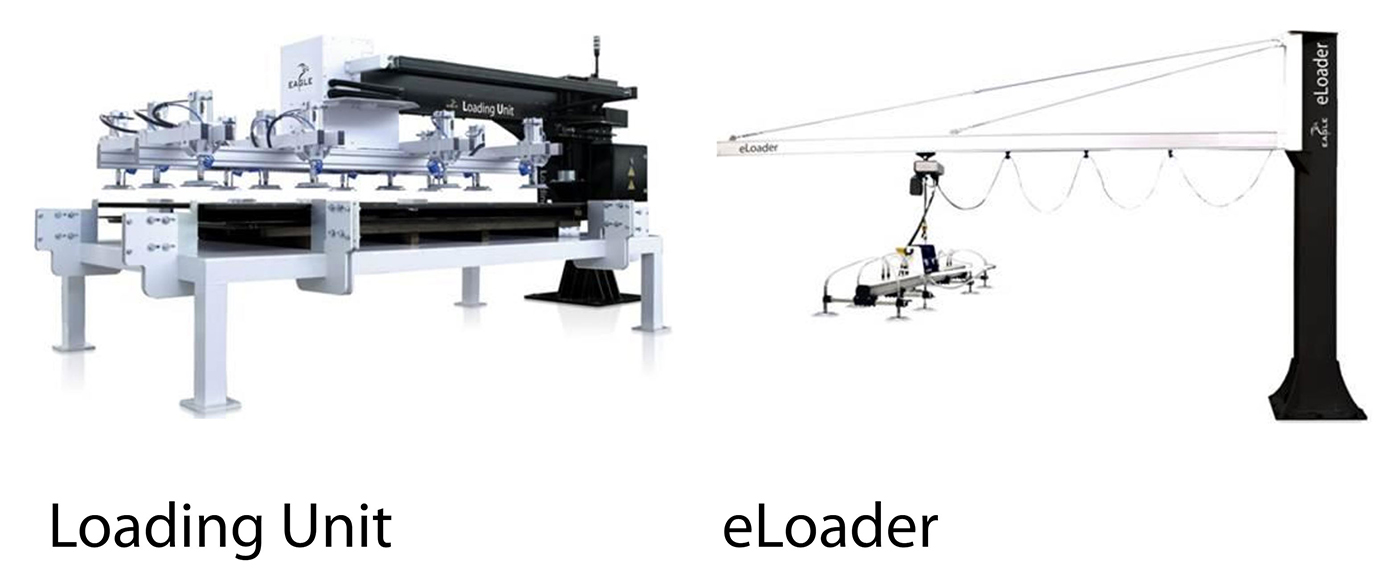

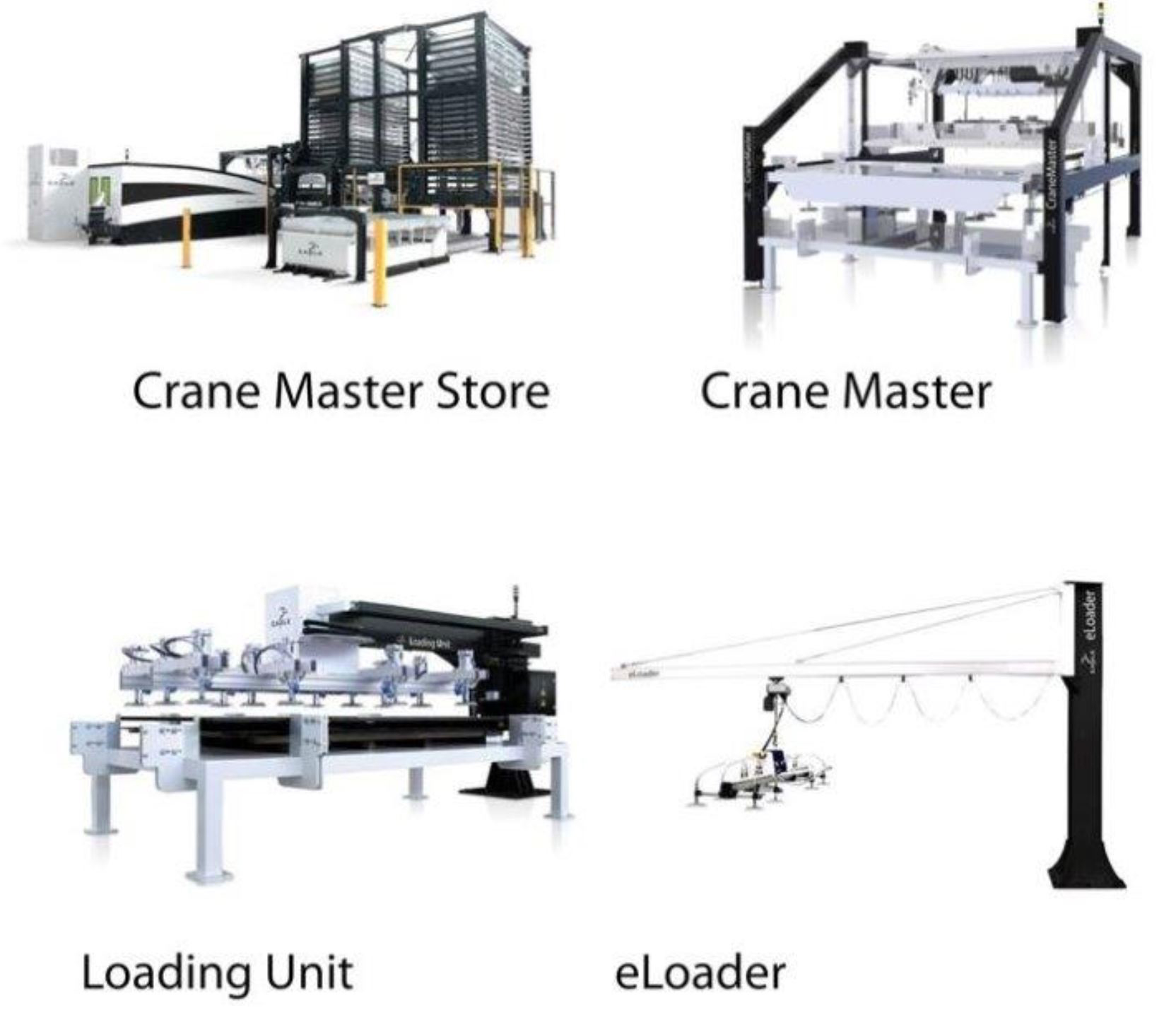

Eagle’s Advanced Material Handling

A laser machine this productive often demands equally productive material handling. Eagle engineers and manufactures a full array of material handling from the manual eLoader to the Crane Master Store with multiple towers.